DIY POWDER COATING KIT FOR HOME

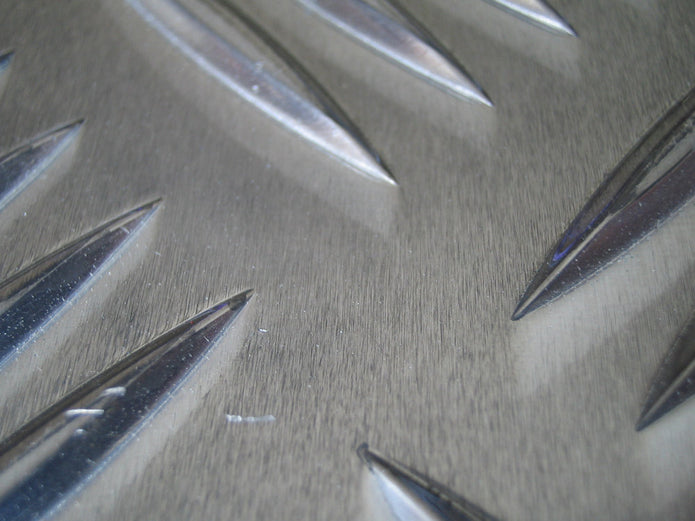

With our Powder Coating Kit, you can now achieve the same high-quality finish that was once only attainable with industrial-grade equipment costing thousands of pounds. Say goodbye to subpar finishes and hello to a world of limitless possibilities in colour and texture for your DIY projects.

What's Included:

Powder Coating Gun, Moisture Separator Filter, Ground Strap with Wristband, 1/4 BSP Universal Fitting, Instruction Manual.

Custom Foam-Lined Plastic Molded Case: Keep your kit organised and protected in our custom-designed case, so you're always ready for your next project.

'Black Gloss' - Achieve a sleek, professional black finish on your projects.

'Ultra High Chrome' - Add a brilliant chrome finish that will make your items shine.

'White Gloss' - Create a clean and classic look with this glossy white powder.

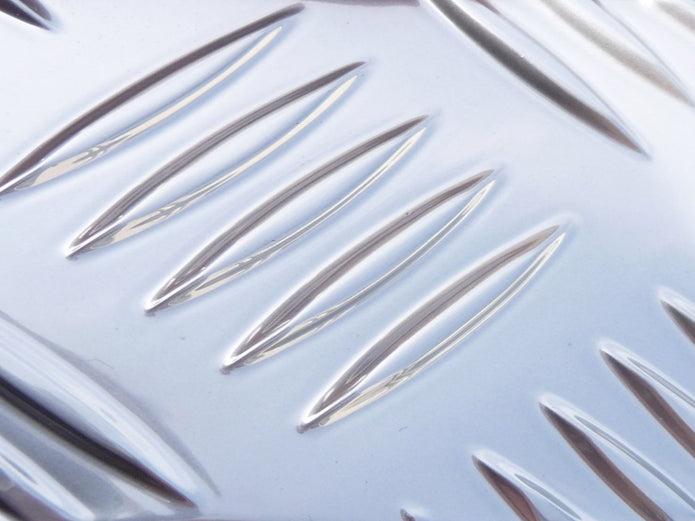

'ULTRA Clear Gloss' - For a transparent, glass-like finish that highlights the beauty of your substrate.

'Red Gloss' - Infuse vibrancy and energy into your projects with this stunning red gloss powder.

AND MORE..

5 x Translucent Plastic Canisters: Convenient containers for storing different powder colours and finishes.

10 x Steel Hooks: Perfect for suspending your items during the coating process.

1 x Respirator Mask: Ensure your safety during powder coating.

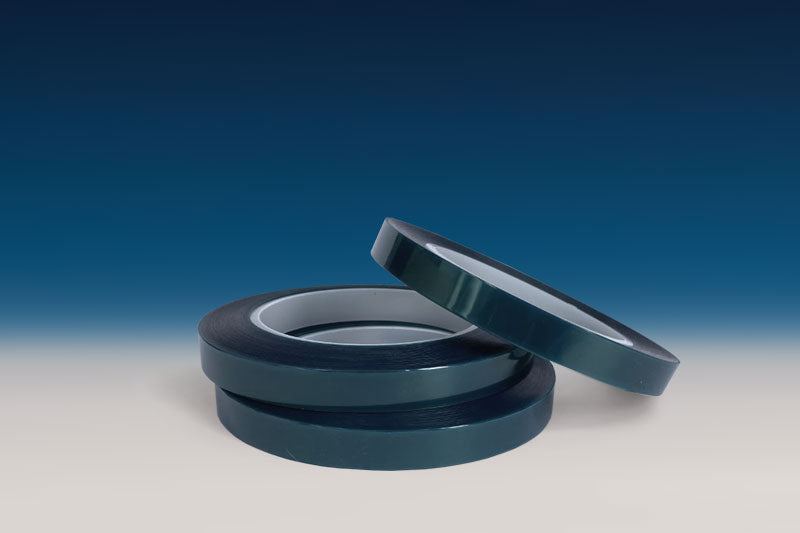

1 x High Temperature GREEN POLYESTER Masking Tape: Precision masking for those intricate details.

1 x Spare System Filter: Be prepared for extended use with this spare filter.